Expertise

We are team of experts with long-time experiences in our branch. We understand both - the machines and the raw materials. Our customers can always rely on our top consultancy and qualified service..

Flexibility

Our clients make products from plastics and we help them to make them in the best way. A truly effective production needs a quick delivery and service of machines. And this is what we are really good at.

Exclusivity

Our clients make products from plastics and we help them to make them in the best way. A truly effective production needs a quick delivery and service of machines. And this is what we are really good at.

We supply machines for plastics processing

Injection Moulding

The injection moulding machines we supply are a guarantee of quality and very efficient processing of various types of materials - especially unfilled and filled thermoplastics, thermoplastic elastomers, 2-component silicone, rubber, metal and ceramic powders. We supply both horizontal and vertical machines - for the production of inserts and overmoulding. Another application is a two-component injection molding machine (or even more) or a separate injection unit for the second component. View products

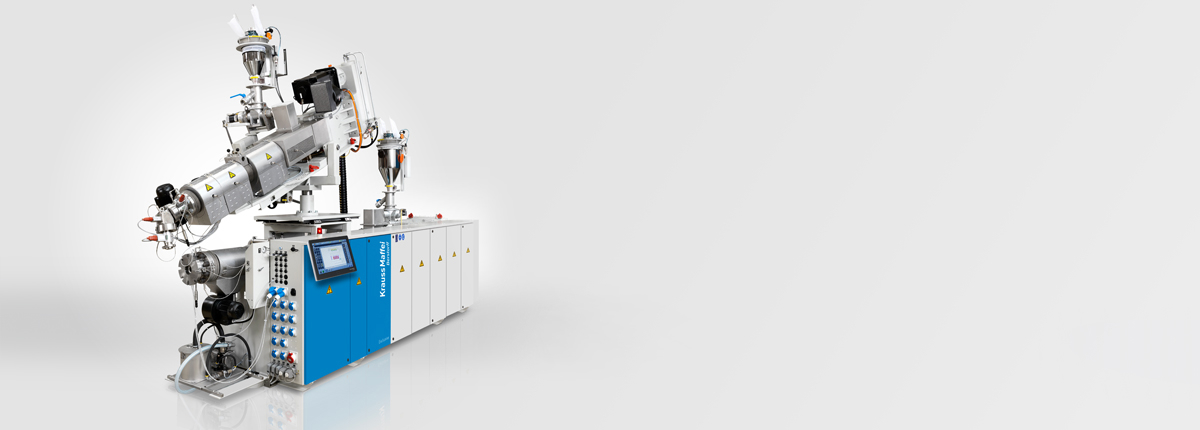

Extrusion

We offer top single-screw and twin-screw extruders from a leading German manufacturer - KraussMaffei Extrusion - which we can supply either separately or supplemented with other components such as gravimetric dosing, screen changers, melt pumps, also in a set for coextrusion in various configurations. If required, we assemble extruders into extrusion lines for the production of pipes, profiles, sheets, or the production of PVC granules.

View products

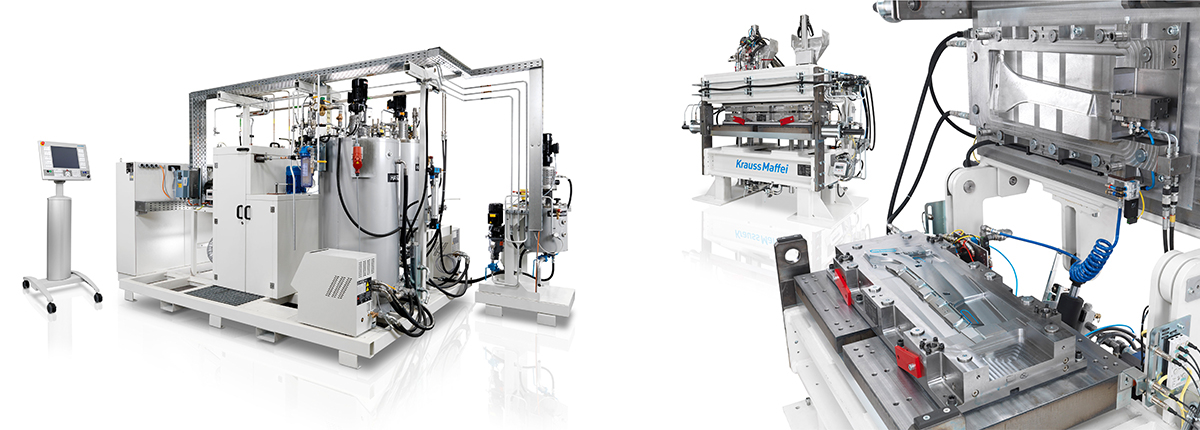

Reactive Injection Moulding

Basic principle of reactive injection moulding is mixing two or more liquids to form a homogenious mixture, which begins to react together in the mould. The mixing takes place by high-pressure dosing into the mixing chamber of the head, which is then automatically mechanically cleaned after each cycle and thus prepared for the casting of the next part. Typical application field is processing of PUR (foamed) systems, but also other materials on a similar processing principle. View products

Processing of EPS, EPP, EPE

We offer all basic machines, from pre-expanders, through block- and shape-moulding machines to recycling or storage equipment, which are needed for the processing of particulate foams EPS, EPE, EPP, E-TPU, various foam copolymers and biopolymers. We can complete the supply of equipment by providing process media, cooling or cutting. View products

Industrial Cooling

Cooling is the basis of every plastics production. Whether cooling injection moulding machines, extrusion lines or blow moulding lines for film production, all production processes need optimal cooling of the process media. Eurochiller industrial cooling equipment can be used wherever process water or air cooling is required. If you are not sure of the required cooling capacity for your production, we will be happy to help with the analysis and design of the optimal solution. View products

Material Dosing and Mixing

Various product applications require various material properties - those can be modified by mixing two or more materials and/or additives such as colour masterbatches, process agents, stabilizers, etc. For a proper functionality of agents, all of them need to be precisely dosed and homogeneously mixed, which is what dosing and mixing equipment is used for. View productsRepresented Partners

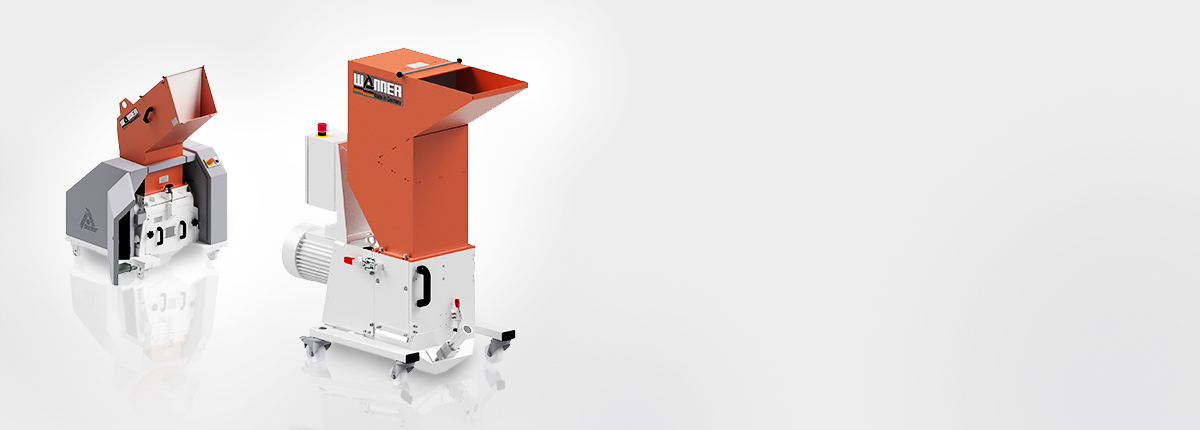

Recycling

Under the term recycling we can imagine the process of full or partial re-use of already processed raw material for new product. Not all materials are "unlimited" recyclable - some of them are really specific and a proven procedure of recycling is needed. We do our best to offer the most modern technologies in order to recycle as much as possible. View products

Material Transport and Drying

There is neccessary to move material from point A to point B in your production. We know how to do that. And if you need to dry this material, we can do it too. We use various types of suction technologies and routes, as well as various types of dryers. We will be glad to prepare a tailor-made offer for you in order to match needs and requirements of your production. View products

Products Handling and Automation

Choose the right equipment that ensures easy transport of products, simplifies the production processes, and enables a more effective finalizing and packaging of products. View products

Temperature Control

The temperature control is important for every plastic processing technology, both during plasticizing/melting and during demoulding/cooling. Regardless whether is it going about injection moulds, extrusion tools or calibration rollers. View products

Extrusion Blow Moulding

For more than 50 years, Plastiblow has been designing and manufacturing blow moulding machines that are characterized by low energy consumption (among the lowest in the industry), high accuracy, high repeatability and minimal maintenance requirement and associated downtime. Mainly thanks to many innovative solutions covered by a number of patents, the machines are applied in various industries around the world, from the production of cosmetics and food packaging, through bottles and canisters for car cosmetics and motor oils to toys, sports equipment and technical parts. . View products

Others

Our portfolio includes also special plastic technologies and equipment. View products

Products Handling and Automation

Products Handling and Automation

Material Dosing and Mixing

Material Dosing and Mixing

Chemistry for maintenance and cleaning granules

Chemistry for maintenance and cleaning granules